About Us

Established in 2003, Innovative Control Technologies is an Industrial Control & Automation solution provider based in Bluffdale, UT. ICTech offers a full range of services, including Industrial Control design and implementation, SCADA System integration, Power Distribution Automation, PLC and HMI programming, Instrumentation, and Control panel design and manufacturing.

Control & Automation solutions for a variety of applications

Industrial Control design and implementation

Our team has decades of experience in providing custom control solutions for a variety of industries, processes, and applications

SCADA System design and integration

SCADA (Supervisory Control & Data Acquisition) systems are becoming increasingly popular to monitor and control geographically dispersed processes

Power Distribution Automation

As the demand for energy is growing at a rapid pace, energy costs are rising, and the infrastructure is aging, Automation becomes increasingly important in availability of distributed energy as well as in energy cost control

PLC Programming

PLC (Programmable Logic Controllers) programming is an integral part of the automation process

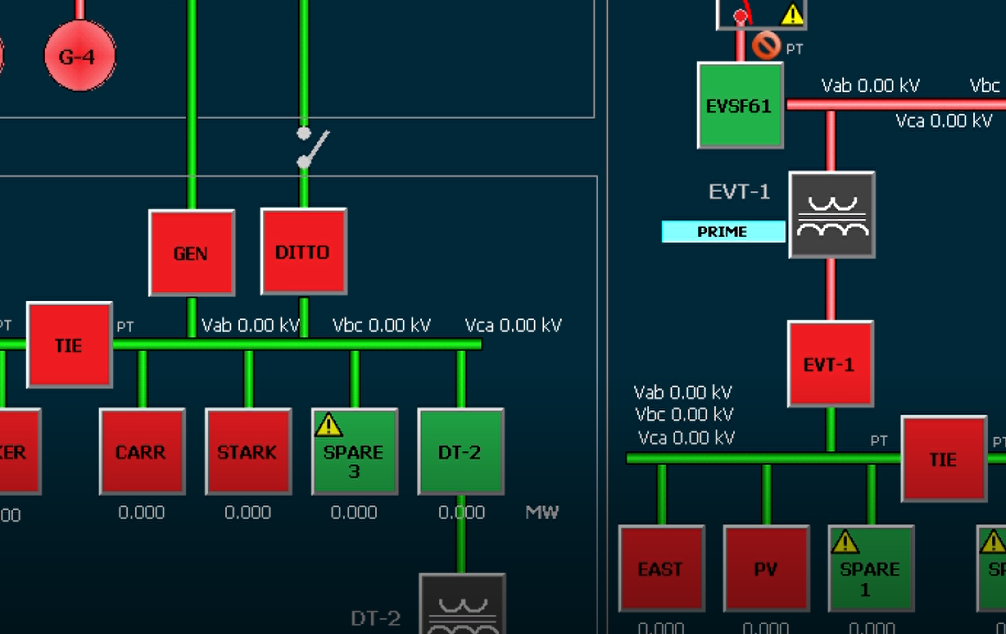

HMI Programming

Human-Machine Interfaces (HMIs) are used to visually convey information to enable the operator to monitor and control a process

Industrial Control Panel design & manufacturing

Our Industrial Control Panel Shop is UL508A certified to fabricate UL listed open and enclosed Industrial Control Panels, and UL698A

Alarm Notification Dialers

Industrial Alarm Notification dialers (also known as Voice Dialers, Alarm Callout systems, etc.) are designed to instantly alert personnel of alarm conditions

Instrumentation

We have wide knowledge of instrumentation in flow, pressure, level and analytical measurements equipment

Industrial Control design and implementation

Our team has decades of experience in providing custom control solutions for a variety of industries, processes, and applications. Our services include optimization, upgrades, and expansion of existing control systems, as well as turn-key delivery of new systems.

We offer a wide array of solution for our clients’ control and automation needs: from evaluation and assessment, engineered system design, PLC and HMI programming, Instrumentation, control panel design and fabrication, to an onsite installation, startup and commissioning.

Each system is supplied with a complete project documentation and CAD drawings package. We provide ongoing and on-demand system maintenance, personnel training, and technical support.

SCADA System Design & Integration

SCADA (Supervisory Control & Data Acquisition) systems are becoming increasingly popular to monitor and control geographically dispersed processes.

ICTech has designed and implemented numerous SCADA Systems of various scale and complexity, including SCADA Systems based on radio, Fiber Optics, serial and Ethernet communication. We work with multiple communication protocols such as Modbus, DNP3, Ethernet protocols TCPIP, DeviceNet, Profibus and others.

We have designed and delivered systems ranging from 20 I/O to over 5,000 I/O points.

While even similar systems are still unique, they are all built on a strict budget, and we help our clients make the most of it. Every time we design a SCADA system, we strive to make it as cost-effective as possible, while making it reliable and user-friendly at the same time. We are always looking for ways to increase functionality and decrease our clients’ costs. Our extensive experience in SCADA design and implementation, and strong practical knowledge of SCADA hardware and software enable us to make an optimal selection of components for a scalable, expandable, and reasonably priced system.

We build non-proprietary (open) SCADA systems, giving our clients ability to “mix and match” components from different manufacturers for better value and greater flexibility. This approach also allows us to incorporate clients’ existing equipment into the new system.

In addition to the design and implementation of brand-new SCADA systems, our team has an extensive expertise in system upgrades, optimization, and migration of data and processes from one platform to another.

Power Distribution Automation

As the demand for energy is growing at a rapid pace, energy costs are rising, and the infrastructure is aging, Automation becomes increasingly important in availability of distributed energy as well as in energy cost control. The objective of the Distribution Automation is to enhance the reliability of power system, power quality, and system efficiency. It collects and analyzes critical data from field-measuring devices and different databases and control systems, for an optimal real-time automated response and adjustment to changing conditions, such as generation, loads, and faults.

Our team has been actively involved in electrical power distribution and electrical industrial applications for over 30 years. Our engineers come from electrical engineering backgrounds and possess strong practical knowledge of Power Automation and Control Systems.

ICTech is experienced in every aspect of Energy and Power Metering, Monitoring and Control – collecting, monitoring, managing, and responding to data from power distribution systems.

Power Monitoring and Control systems provide solutions for:

- Real time power quality monitoring

- Identifying issues with power quality

- Load optimization

- Evaluation of system transfer capacity based on real-time measurements

- Immediate response to events/alarms/faults

- Energy consumption optimization

- Improvement of power reliability

- Energy metering for widely dispersed infrastructures

- Power loss management

- Energy cost control

- Accurate projection of future energy costs

- Access to historical usage data

- Reducing facilities and operations operating costs, etc.

Our engineers have designed and delivered Power Control systems of various sizes and complexity for switchgears, substations, data centers, solar plants, correctional facilities, universities, and hospitals.

We have extensive experience with the following equipment:

- SEL (Schweitzer Engineering Laboratories): RTAC (Real-Time Automation controller), Protection relays, PQMs (Power Quality Meter), Network devices.

- NovaTech: OrionLX Substation Automation Platform Controller

- Schneider Electric: Protection relays, PQMs

- Eaton: PQMs

- GE: Multilin protection relays, PQMs

- Siemens: Protection relays & Automation, PQMs

PLC programming

PLC (Programmable Logic Controllers) programming is an integral part of the automation process. There is more to delivering a quality, sound program than just coding. It also requires understanding of the process and excellent communication with a client.

Our programmers have extensive hands on start-up, maintenance, and troubleshooting experience with various systems and processes, and strong technical knowledge that goes beyond just programming. When creating a program, we know what questions to ask and what we need to pay special attention to.

Depending on the final application, software platform, and client specifics we use the following programming methods: Function Block Diagram, Instruction List, Ladder Logic, Sequential Flow Charts, and Structured Text. We write clean and functional programs that are easy to maintain and easy to modify in the future.

Our programmers are experienced in the following PLC platforms:

- Allen-Bradley

- GE Fanuc

- IDEC

- Koyo AutomationDirect

- NovaTech

- Red Lion

- Rockwell Automation

- SEL (Schweitzer Engineering Laboratories)

- Siemens

- SquareD Modicon (Schneider Electric)

- WAGO

- and more

HMI programming

Human-Machine Interfaces (HMIs) are used to visually convey information to enable the operator to monitor and control a process. The HMI can be described as a combination of built-in physical displays, custom graphic displays used by the operators, and other similar hardware and software items.

There is no “standard” HMI to adequately represent every process. Every system’s HMI is custom. ICTech has extensive expertise in providing HMI solutions for a wide range of processes and applications.

Our approach to HMI design comes from decades of experience and operator feedback. When we create operator interface screens, we utilize intuitive design and layout, and clean, easy to read graphics.

Our team has wide experience with the following Local Operator Interfaces (HMI) and SCADA HMI graphic packages:

Local Operator Interfaces (HMI):

- Allen-Bradley

- Beijer

- Cmore (AutomationDirect)

- EZTouch

- IDEC

- And many more

SCADA HMI graphic packages:

- Cimplicity

- ClearSCADA

- GE iFIX

- Ignition

- Indusoft

- iX (Beijer)

- Lookout

- Mango Automation

- RSView

- TeslaSCADA

- VTScada

- Wonderware

- And more

Alarm Notification Dialers

Industrial Alarm Notification dialers (also known as Voice Dialers, Alarm Callout systems, etc.) are designed to instantly alert personnel of alarm conditions. The notification options of Alarm Dialers include Voice, SMS, email, Mobile Apps, and annunciation over any networked audio device. There are dozens of options of notification dialers by various manufactures on the market. We have experience with Win 911, ProTalk, Sensaphone and SCADADroid.

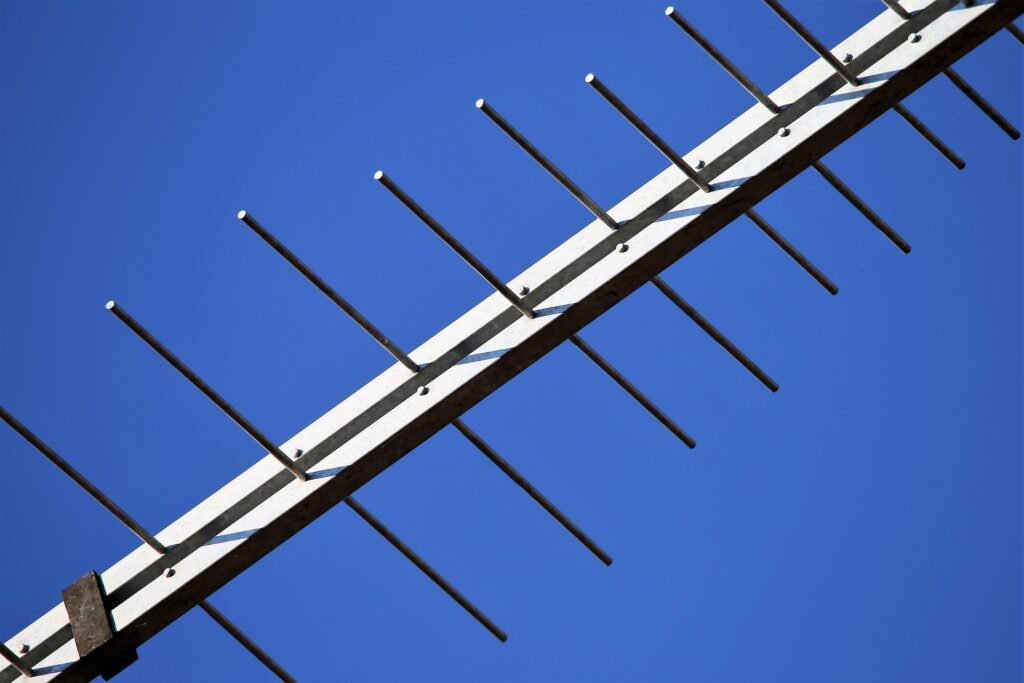

Telemetry

Telemetry refers to the automatic measurement and transmission of data at a distance by radio, cellular or other means. We have extensive experience with telemetry applications based on radio, ethernet, fiber optic and cellular communication. We have utilized the following equipment in our telemetry installations: Cradlepoint, Trio, Freewave, SEL, Sierra Wireless, MDS, etc.

Instrumentation

We have wide knowledge of instrumentation in flow, pressure, level and analytical measurements equipment. We design, size and specify instruments per project documentation, data sheets, submittals & O&M Manuals to indicate, measure and control specific aspects of a production process. Our engineers and technicians are experienced in instrumentation startup and calibration.